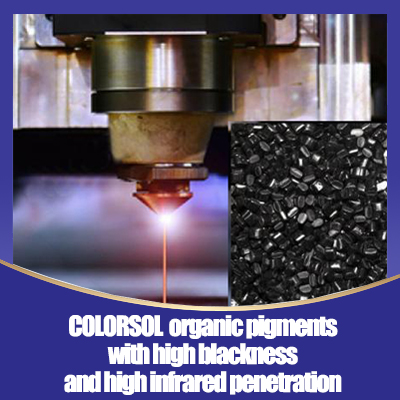

Infrared welding has many advantages such as fast, efficient, energy-saving, environmental- friendly and so on. Compared with traditional welding methods, infrared welding can greatly reduce heat transfer losses and material consumption, so that improving production efficiency and reducing production costs, thus it has been accepted and promoted by a large number of customers. D-RAY's COLORSOL and COLORSTEP® products have good infrared penetration effects, and have been widely used in the penetration layer of infrared welded engineering plastics and polyolefin products.

Organic black pigments with high blackness and high infrared penetration

Excellent heat and weather resistance

COLORSTEP - Excellent migration resistance in polyolefin systems

COLORSOL - Particularly suitable for high temperature engineering plastics applications

Guangzhou Wisdom Chain

Co.,Ltd.

Guangzhou Wisdom Chain

Co.,Ltd.