two-component, solvent-free, 100% solids, modified polyamine cured epoxy intumescent fire protective coating.

Meeted by API2218 and NORSOK M501 as hydrocarbon fire resistant intumescent products.

The products meet the CCCF certification of the fire protection product conformity assessment center of the Ministry of emergency management of the People's Republic of China.

Tested and evaluated according to the technical specification of GB 14907-2018 ‘fire resistive coating for steel structure.

T&H ThermoChar 714 it is applicable for the fire protection of steel structure such as steel column, steel beam, support, floor and steel wave plate in steel structure, including the fire protection of ordinary cellulose fire and special hydrocarbon fire, such as facilities and equipment in petroleum and petrochemical industry, metallurgical and electric power industry, civil steel structure building, sports hall, airport, station, large shopping mall and industrial plant, etc.

All surfaces shall be free of oil, grease, dust or any other contamination prior to coating. Application of the product shall occur strictly in accordance with the T&H ThermoChar 714Application documents.

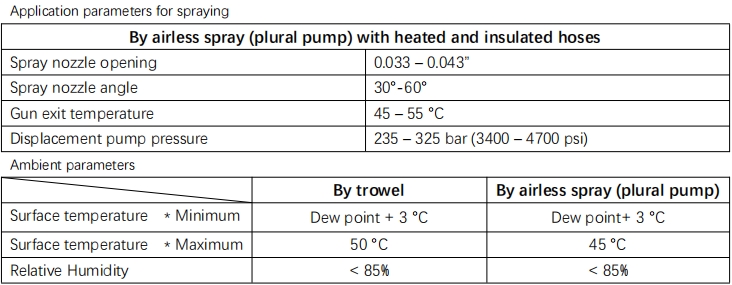

The product can be applied by trowel (immediately apply the product after mixing) or by plural component airless spray with heated and insulated hoses (e.g. WIWA DuoMix 333PFP or Graco XM 70 or Graco XP 70).Contact your T&H Technical Service representative for more information.

The base material should be sandblasted to SA2 ½ (ISO8501-1) and apply suitable primer(must be approved by T&H company) before application. Thoroughly remove grease, etc. with appropriate detergent, and clean salt and other pollutants with high-pressure clean water.Soluble salt contamination shall be checked in accordance with ISO 8502-6 for extraction of contaminants and ISO 8502-9 for quantitative determination. The maximum allowable content shall not exceed 3µg/cm² for Carbon Steel and 2 µg/cm² for Stainless Steel. If the antirust coating is damaged, it must be repaired before the construction of the fire retardant coating. If the steel structure has been coated with antirust paint, attention must be paid to the matching between primer and fireproof paint.

Individual components should be heated in accordance with the temperatures in the table below. When applying by trowel, the application performance can be improved by mixing 5% of the appropriate epoxy diluent at low temperature.

Primer. T&H ThermoChar 714 this product can only be applied to the primer approved by T&H company. Please consult our technical representative for the primer approved by T&H company.

Thinner. When applying by trowel, the application performance can be improved by mixing 5% of the appropriate epoxy diluent at low temperature.

Cleaner. All tools and equipment shall be clean prior to use and should be cleaned after use. Do not allow material to remain in the hoses, gun or other spray equipment. Clean the material regularly and always clean the material immediately after the coating application is finished. Humiclean should be used as a cleaner. Make sure no remnants of XH9426 remain at tools or equipment prior to use. Other cleaning agents should be approved by your T&H representative.

Mesh. The net must be mounted when needed,this should be carried out in accordance with the ThermoChar 714 APPLICATION GUIDELINES install CHAR BXF mesh.

Topcoat. A topcoat is nice to have for corrosion or fire protection properties.

T&H ThermoChar 714 can be used to repair other PFP coating systems and is compatible with other fully cured PFP epoxy coating systems. Compatibility shall always be confirmed by your T&H representative.

Only personnel who have completed a formal qualification and training programme carried out by T&H or approved representatives and are in the possession of a valid T&H ThermoChar certificate, shall apply T&H ThermoChar.

The coating inspector shall be minimum NACE Level 2 or approved equivalent. A minimum of 5 years of expe-rience in the application of epoxy intumescent PFP industry is required. Inspection shall be carried out in linewith the manufacturer’s recommendations.

For technical services and other support, please contact your T&H representative.

| STANDARD PACKAGING | Component A | Component B |

| Unit Size: 60kg(One set) | Part A: 23.02kgX2 | Part B: 13.96kgX1 |

All work related to the application and use of this product must be carried out in accordance with various relevant national health, safety and environmental protection standards and regulations.

For additional documentation such as the Application Guide, Extended Application Manual, SDS and other documents, please contact your T&H representative.

The products must be stored in accordance with the national regulations.

All personnel applying the product must refer to the applicable SDS, precautionary notices on the pails, and ensure they wear appropriate PPE, including eye protection, breathing filters suitable for protection against vapours, gloves, boots and long sleeve flame retardant shirts and trousers. Ensure that adequate ventilation isto be provided in the workspace and exclude non-essential personnel during coating application.

The information provided in this product data sheet is based on the accurate laboratory test results as we consider, and is only for application guidance. T&H's opinions and suggestions on the application of T&H products, whether in technical documents, special consultation or other ways, are based on the most reliable information we consider. The products and the information we provided are designed for users with the necessary knowledge and industrial experience. It is ultimately up to these end customers to decide whether these products are suitable for their application. T&H are unable to control the quality and condition of the substrate, and also are unable to control the various factors that affect the application of products. Therefore, T&H will not undertake any loss, injury or damage caused by using our products or quoting the product data sheet( unless otherwise agreed in writing).

We will make necessary changes to the product data sheet according to the actual experience and the needs of the continuous development of the product.

Guangzhou Wisdom Chain

Co.,Ltd.

Guangzhou Wisdom Chain

Co.,Ltd.